When it is about long-term storage, the moisture balance in a cold store is crucial. Too much moisture loss leads to weight loss, but also to a product that is less easy to store. The quality of fresh product deteriorates, and in the case of fruit it usually starts to wrinkle. Bringing moisture back into the fruit is not possible, so the only option is to prevent moisture loss during storage. On the other hand, there are also products (Elstar and Kanzi apples) that have to lose moisture to a certain extent in order to be able to store them properly.

The so-called water meter has been developed to monitor the loss of moisture. It collects the water that is released from the evaporators in a cold store during defrosting. Because a CA cold store is a closed system, the measurement of this loss actually indicates how much moisture the fruit loses per unit of time. Then only the exact tonnage of the cold store needs to be known in order to be able to calculate the percentage of weight loss. Each cold store is usually equipped with its own water meter.

How does the moisture loss measurement work? Fresh product will lose water continuously in a hermetic CA cold store. This causes the relative humidity (RH) to rise. At a certain point the fruit can no longer lose moisture, because the RH is around 95-98%. However, during each cooling action, water freezes on the evaporator and this lowers the RH and frees up space to lose moisture.

The smaller the delta T across an evaporator (the difference between the temperature of the cooling medium and the surrounding air), the less water will freeze. Therefore, cooling systems that work with large evaporators (with a large lamellae surface) and a small delta T are beneficial to prevent moisture loss.

During a defrost action (electric, hot gas) the meltwater runs into the drip tray under the evaporator. A drain has been fitted at the lowest point of this drip tray, which takes the water outside the cold store through a siphon (to keep the system gastight). The water is then discharged to the sewer.

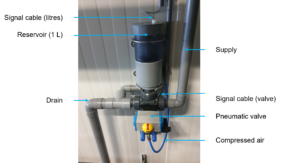

If a Blue Atmosphere water meter is installed, this drain is interrupted on the corridor to determine the loss of water. The device has a storage volume of 1 litre and is equipped with a float. This indicates exactly when the volume of a litre has been reached. At that moment a pneumatic valve is switched that ensures that the water can still continue its way through the drain. After the water has drained, the valve returns to its original position. At the same time, the water meter gives a pulse to our cold store controller (a Siemens Climatix). This controller communicates the litre of moisture loss with our Scada user interface. This is where the litres of moisture loss and weight loss per cold store are recorded.

The connection of a water meter, therefore, consists of a supply and discharge (PVC pipe, 32 mm), which is usually installed by the cooling company. Blue Atmosphere usually lays the signal cables (an input, the float indicates that the reservoir is full, and an output, switching valve) and the compressed air hose for the pneumatic valve (6-8 bar).

Moisture loss measurement gives a good indication if your cooling system needs adjustment, and how long fresh product can be stored. Water meters are highly recommended for the storage of a number of products (pears, some apple varieties).