Why is dimensioning Controlled Atmosphere machinery so important? We would like to pay a little more attention to this. This mainly concerns the CO2 adsorbers.

Optimal CO2 values in a cold store are different for every fruit or vegetable variety. Even for different cultivars and growing locations, they can be different. For example, some apple varieties are sensitive to CO2, because high values can cause internal browning. On the other hand, the principle applies: the higher the CO2 value, the stronger the respiration of apples is suppressed, and the better the ground colour. Optimal values for apples are usually between 0.8% and 4.0%.

When we start dimensioning, we assume a CO2 adsorption capacity per 100 tons of product as standard. The amount of CO2 that has to be removed per 24 hours is between 10 and 50 kg. There are two parameters that determine the adsorption capacity required:

- The respiration rate of the product. This determines how much CO2 is produced per unit of time.

- The optimum CO2 value for the storage of the product, in other words the value that is set for a cold store.

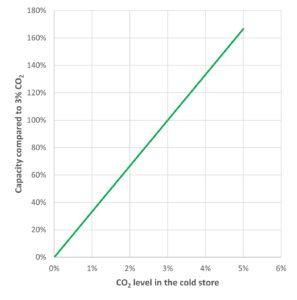

This CO2 value in the cold store is often not taken into account at all, while activated carbon binds much more CO2 at higher CO2 values. The relationship between the two is almost linear between 0.5% and 5.0% CO2. To clarify this point, if you decide to store your apples at 1.5% CO2 instead of 3.0%, you will need adsorbers with a capacity that is twice as large. That is quite something!

Both parameters make for a big difference, because the adsorption capacity needed for apples alone can vary by a factor of 15! That is why we always ask the annoying question: what are you going to store, and under what conditions? The intention of this is good, because the more precisely we know what you are going to do, the more accurately we can calculate. Otherwise we have to start from general values, which can lead to much higher costs. Because, we of course want to prevent you from running out of capacity.